——ABOUT US

—— Our company Canmak Makine in TURKEY/Antalya serves the printing industry and printers with the most affordable price and the most favorable payment terms in all kinds of machinery with its staff specialized in used printing machines for 25 year.

Product

Frequently Asked Questions

- Pre sales service

- Sales service

- After-sales service

- Maintenance of the machine

Provide customers with professional and complete product introduction and selection information so that customers can clearly and conveniently determine their needs and customize products for customers.

Professionals provide customers with design and consulting services and recommend the most suitable products for customers’ actual needs.

Provide users comprehensive technical support, cooperate with user selection, and provide the most economical and reasonable product solutions.

Provide users with free product training, installation guidance, and maintenance methods to determine the best service plan.

Strict supply chain management process control and contract spirit provide customers with timely delivery of products.

During the warranty period, users will enjoy free warranty service. At the same time, Guohao Machinery promises to provide lifelong value-added services for all products during their life cycle and to provide original accessories.

On-site installation guidance, auxiliary debugging, monitoring operation, daily maintenance, and maintenance services.

Offices have been set up, promising to arrive at the scene within 8 hours in the city, 24 hours in the province, 48 hours outside the province, and 72 hours in remote areas.

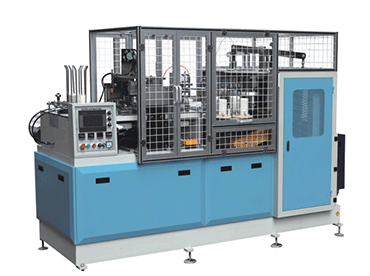

Only by regularly maintaining and maintaining the paper cup machine and improving the working conditions of the machine can the user keep the machine in good working condition and prolong the service life of the machine; the specific methods are as follows:

Do a good job in daily inspection, and add EP150 gear oil or lubricating grease to the movable joints and mechanical moving parts above the work board.

Check whether the cylindrical pin and elastic retaining ring of the mechanical connection part are in the normal position. If there is a discrepancy, it should be corrected immediately, or the retaining ring should be replaced.

Check whether the fasteners are tightened: if the nuts and bolts are loose, they should be tightened in time, otherwise it will cause serious problems such as violent vibration of the machine, disordered stroke or even collision.

If you find any abnormal sound or abnormal situation in the work, you should stop the machine immediately and check it carefully.

Troubleshooting of mechanical faults should be carried out by personnel with mechanical knowledge and experience in machine repair to ensure the safety of personnel and machines.

The oil inlet filter of the oil pump of the lubricating system should be cleaned regularly (to avoid the blockage of the oil circuit and the inability to supply oil to the places where oil is needed, resulting in serious wear of the machine). Clean it once a month to ensure smooth oil passage and proper lubrication.

The lubricating oil (EP150) also needs to be replaced regularly. The new machine needs to be replaced once in the first month, and then it can be replaced once every 6 to 12 months to ensure that the machine is well lubricated and prolong its service life.

The light eye should be cleaned regularly. Generally, the light eye head should be cleaned once every 3 to 5 working days to ensure the normal inspection of the machine operation.

The filter screen on the high pressure blower should be cleaned every 7 working days to ensure smooth ventilation.

For each manually lubricated part on the machine, a professional lubrication schedule should be formulated to achieve regular refueling, regular oil change, and regular cleaning.

Sample display Paper Cup (paper container)

The paper cup is a kind of paper container made of mechanical processing and bonding made of chemical wood pulp for mechanical processing and bonding.

Paper cups used for frozen foods can be painted with ice cream,jam and butter.The paper cups used in heating drinks are coated with a temperature above 90C,and can even boil water.

The characteristics of paper cups are safe,hygienic,light and convenient.

Public places,restaurants,and restaurants are available for use.