Automatic Paper Bag Making Machine (2018 New Model)

- Adjustable roll to square bottom bag making machine

- Introduce In-touch screen human-machine interface, easy for correction and fine adjustment. Alarm and working status can be displayed in screen on-line, easy for operation and maintenance.

- Equipped with PLC for centralized control system and SICK photocell for correction, tracking the printed material accurately, minimize the adjustment and preset time, increase the production efficiency.

- Human oriented security protection, whole housing design, ensure the safety of operator.

- Physiosisroller hydraulic material loading system with chuck, hydraulic up/down system

- Automatic constant tension control for unwinding, EPC web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment.

- High speed oriented design ensure successful of production: within the suitable paper range, production capacity can reach 150~180pcs/min, even higher,which increasesthe unit production capacity and gets higher profit.

- Original SCHNEIDERelectric system, ensure better stability and reliability; perfect after sale service, trouble free for customer.

- Machine Introduction

- Technical Parameters

- Sample

- Company

Specification

Adjustable Roll to Square Bottom Paper bag making machine

Application: This machine is designed to manufacture square bottom paper bags from paper roll in blank or printed. Side gluing, tube forming, cutting, bottom creasing, bottom gluing, bottom forming and final product out feed can be completed within one time by this machine. It is ideal equipment for making paper bag for foodstuff bag, shopping bag and so on. Controlled by PLC system, equipped with in-touch screen and servo motor for bag length control, this machine can produce different size paper bag.

Main Configuration

1.Unwind Section

1.1, Structure, Features:

(1) Separated single unwind rollstand with hydraulic lift device.

(2) Physiosis roller for paper roll loading, the load arms are driven by two hydraulic cylinders separately, can be adjusted freely.

(3) Magnetic powder brake and constant auto tension control for unwinding tension control.

(4) EPC (electronic program control ) web guide system for material alignment.

1.2, Parameter, Specification:

(1) Unwind Roll stand (1pc)

(2) Hydraulic lift device for material load (1set)

Hydraulic Cylinder 100X500 (1pc)

Motor for hydraulic pump(1.5kw)(1unit)

(3) Roll load Arm Switching device (1set)

(4) Physiosis roller chuck device (1set)

(5) Magnetic Powder Brake (100N.m) (1unit)

(6) Tension transducer (1pc)

(7) EPC web guider system for material edge alignment (1set) Sensor, Motor for drive, Hydraulic Cylinder, Hydraulic Pump etc

2.Material In-feed and side gluing Section

2.1, Structure, Features:

(1) Separated Material In-feed section

(2) using automatic side glue system, (by air pump), no need add glue by hand.The automatic spray glue, the glue spray will not be interrupt when high speed or low speed, convenient adjustment capacity, glue spray stable .high pressure can save glue, easy and simple to use without cleaning, saving cleaning and saving glue.

3.Tube Forming Section

(The whole type tube is used to adjust the structure, and the two-way adjustment or one-way adjustment is simple and convenient, and the fast and precise high stability of the adjusting is stable.)

3.1, Structure, Features:

(1) Whole unit tube forming frame

(2) Forming Mould Support Design, Adjustable Former Support for Precise Former Alignment, Adjustable Pressing Wheel.

4.Bottom Forming Section

The machine cut off way adopts the servo motor to control the paper bag size, adopting high-speed uniform rotation cutter, cutting through the tooth knife or flat knife two cutting methods, the paper bag cutting level,making the paper bag cutting Flat, let bag beautiful.

4.1, Structure, Features:

(1) Material feeding by INDEPENDENT SERVO Draw roll Drive System, Photo Cell System for Running Preprinted Materials (No Change gears)

(2) Rotary Serrated Cutoff with Elliptical Gears

(3) Adjustable Bottom Score Device, can adjust the bag bottom size,

(4) Bottom Opening Cylinder with Split Cam for Full Range Stretch Adjustment

(5) Multi Layer Bottom Forming Drum, Center Grippers, Second Tuck Clamps, and Drum Fingers are adjustable for ease of changeover.

(6) Bottom Glue Applicator with Pneumatic Cylinder for engagement

(7) Bottom Impressing Roller with up/down Feature for Easy Operation

(8) Motor : Servo motor (2 pcs)

Bottom glue system

Using automatic suck glue by air pump from glue tank,when glue less than sensor,the air pump will working add the glue automatic .reduce working time and Clean.

5.Bag Delivery Section

5.1, Structure, Features:

(1) Side Table Delivery with Belt for easy operation

(2) Rubber impress roller for Bag Shape Fixation

5.2, Parameter, Specification:

(1)Delivery Table……………………………………………………………………..1set

(2)Conveying Belt ………………………………………………………………….. 2pcs

(3)Rubber impress roller for Bag Shape Fixation………………………….1pcs

6.Control Section

6.1, Structure, Features:

(1) PLC centralized control for whole machine.

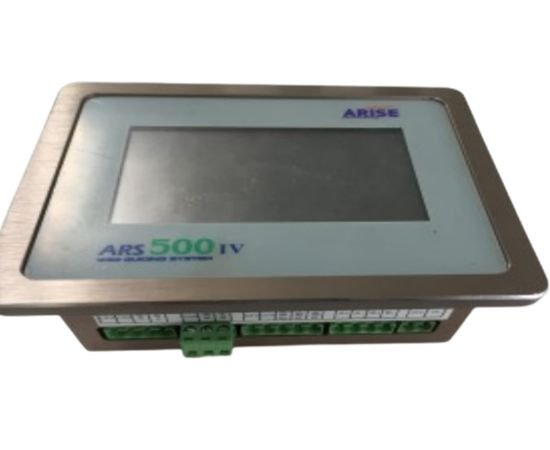

(2) Human-machine Interface: Touch Screen Operator Control. Easy to change Machine Settings & Monitoring.

Parameter,Specification:

(1) PLC(inovance CHINA)……………………………………………1unit

(2) In-touch Screen 10″(MCGS CHINA)………………………1unit

7.Configuration

(1) Main Components introduce NSK ball bearing from Japan

(2) Motion controller Trio( ENGLAND).

(3)Low Voltage Components: SCHNEIDER.

(4) Edge controller using Italian SELECTRA(ST)

(5) SICK(Germany) photocell for correction, tracking the printed material accurately

(6) Servo Motor inovance,and Electric equipments SCHNEIDER.

Top view of the technical parameters

After Sales Service

Installation:

The seller will send total 1 engineers to install. 1 engineer to install and test the printing machine and train customers’ workers in buyers’ factory. It will take 12 days for whole installation and training.

The buyer should cover engineers’ salary, visa cost, Round air tickets, accommodations, transportation in buyers’ country, food, medical care, safety cost, and related cost happens in buyers’ country. Also, the buyer should prepare enough labor, electric wire outside the control panel and tools for installations.

Engineer’s Salary:

USD 120/day, depending on how the engineer make you satisfied. The date he arrives and leaves shall be counted as paid day.

The dates which wait for spare parts coming on seller’s duty are exclusive of salary paying.

Warranty:

Warranty period for the delivered equipment will be 12month after completion of erection but not later than 18months after shipment. In case any item proves to be defective and the damage is confirmed by seller’s technicians within this period, the seller will at their choice either send engineer to repair or supply a new one for replacement free of charge on the basis of CNF delivery.

The above item does not include the parts, which have regular spares or the parts damaged from normal wear, abnormal operation, improper maintenance and inadequate civil works. The seller is not liable for any production loss under any circumstances.

Packing:

As per export standard, they will also be treated before delivery against damage and rusting.

| Model | SBR-330 |

| Width of Paper roll | 320-930 mm |

| Length of Bag | 225-470 mm |

| Width of Bag | 150-330 mm |

| Width of Bag Bottom | 60-160 mm |

| Paper weight | 60-160 g/m2 |

| Max. Diameter of Paper Roll | ф1500 mm |

| Internal Diameter of Roll Core | ф76 mm |

| Max.Speed | 180 pcs/min |

| Total Power | 15KW |

| Weight of Machine | Approx 6500 kg |

| Overall Dimension | L 8800 mm × W 2500 mm × H 1900 mm |

SanLin Machine

The company pays attention to technological transformation, strives to improve equipment performance, manufactures excellent products that meet customer needs, and provides timely and reliable after-sales service. Therefore, it has been unanimously praised by users in the same industry and at home and abroad. The company adheres to the corporate belief of “people-oriented, pursuit of excellence” and the business tenet of “reputation first, customer first”, focusing on scientific and technological innovation, and the principle of winning by quality, and constantly improving the internal management and after-sales service of the company to ensure that it provides and meets customers As for the requirements and product service, SanLin Enterprise warmly welcomes new and old customers to visit and patronize.

wqe